|

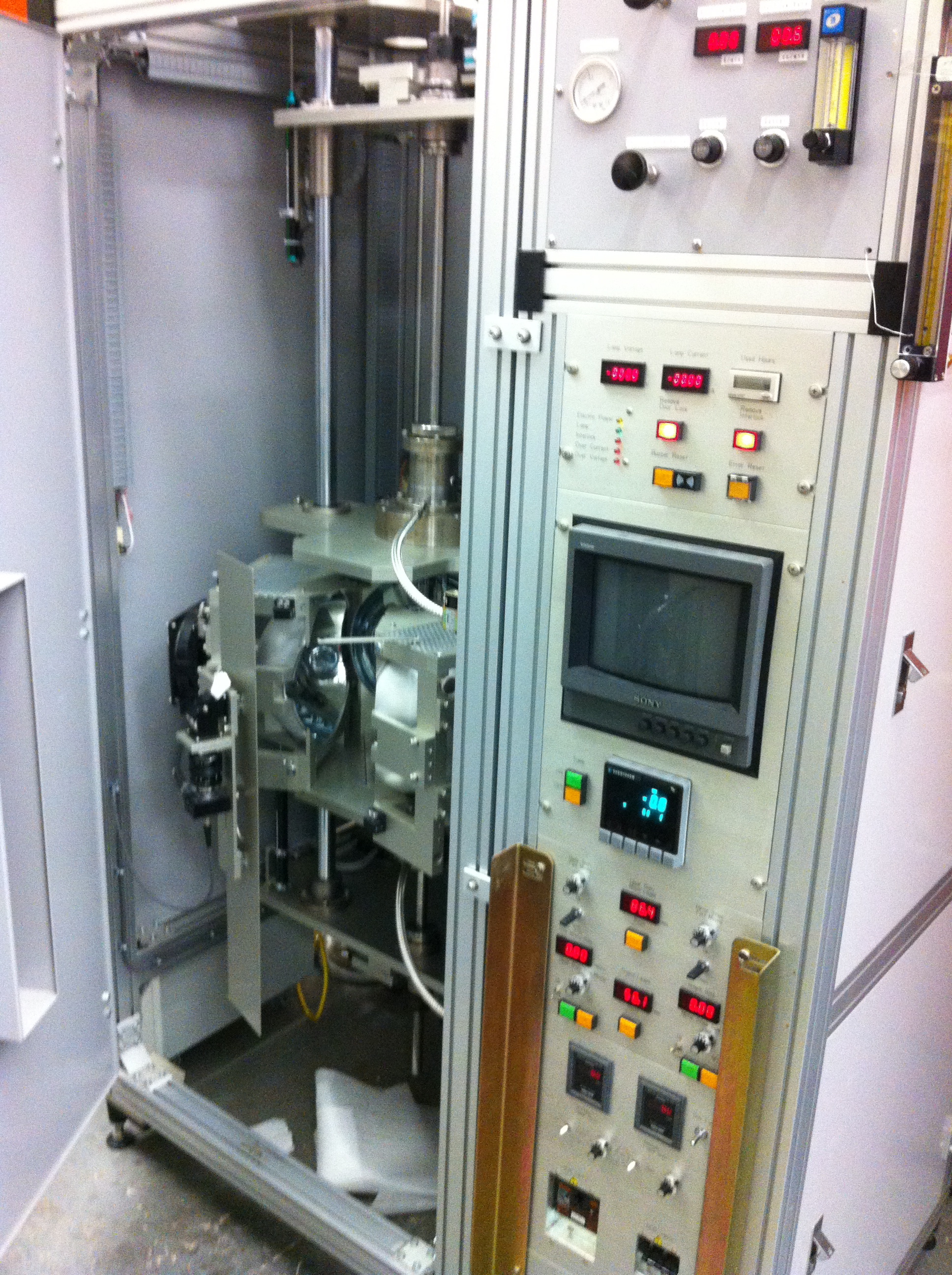

Czochralski Furnace

Powerful Czochralski furnace can be used to grow large size, high melting point oxide single crystals, such as YAG, YAP, GGG, saphire, etc. The furance is equipped with electronic balance system and automatic diameter control software for high precise and reliable crystal growth process. |

|

Multiprep polishing system

The multiprep system enables precise semi-automatic sample preparation of a wide range of materials to achieve an roughness of 1 nm. Capabilities include parallel polishing, angle polishing, cross-section polishing or any combination thereof. Dual micrometers (pitch and roll) allow precise sample tilt adjustments. Digital indicators enable quantifiable material removal, which can be monitored in realtime. |

|

Precison ion polishing system (PIPS II)

The precision etaching coating system (PECS) II is a table top broad beam argon milling tools for polishing as well as coating samples. Tunable energy milling from 0.1-8 keV to reduce amorphous layer or a high milling speed. Liqiud nitrogen specimen cooling can be used to eliminate artifacts and a digital imaging microscopy system is equipped. |

|

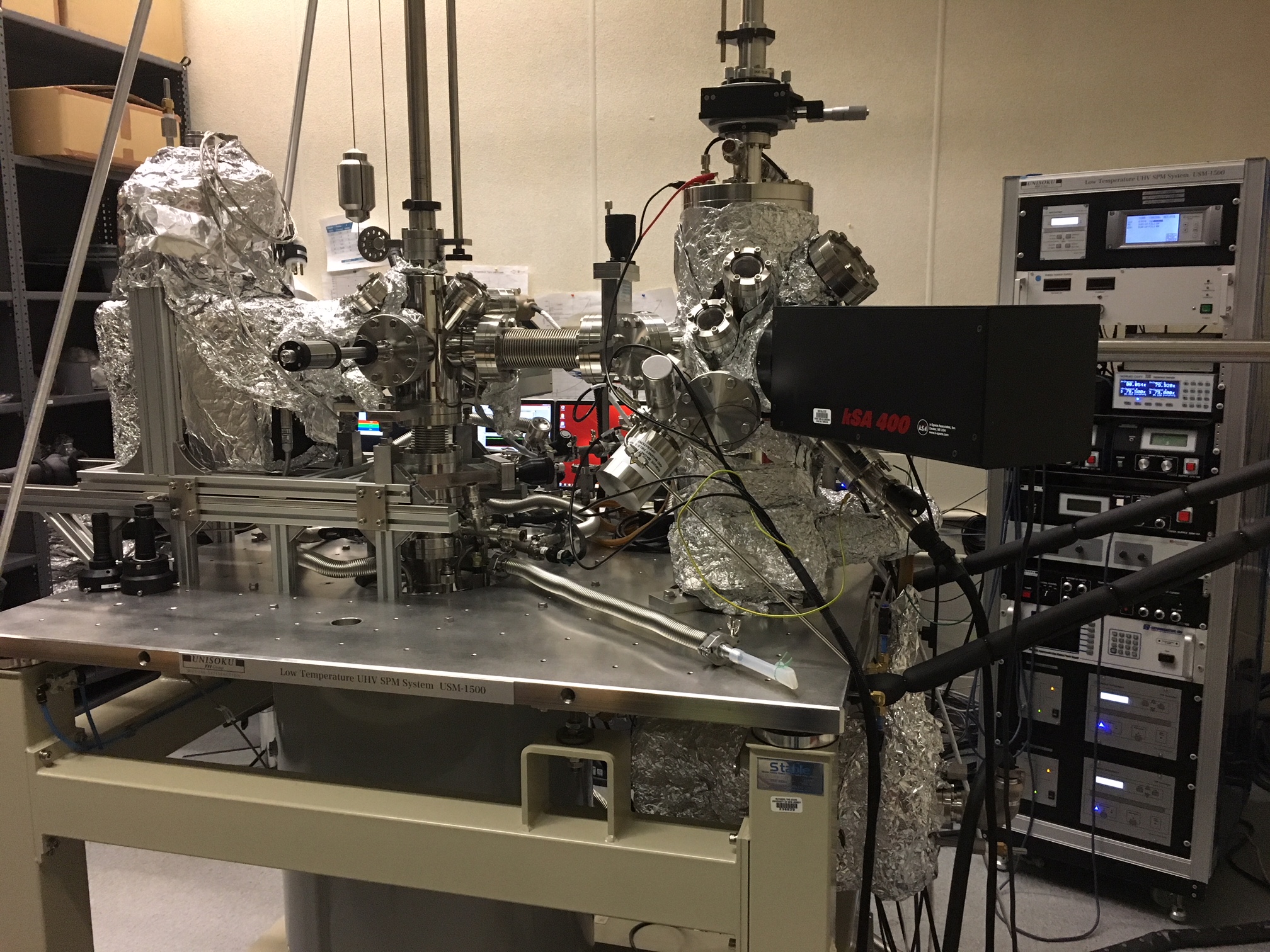

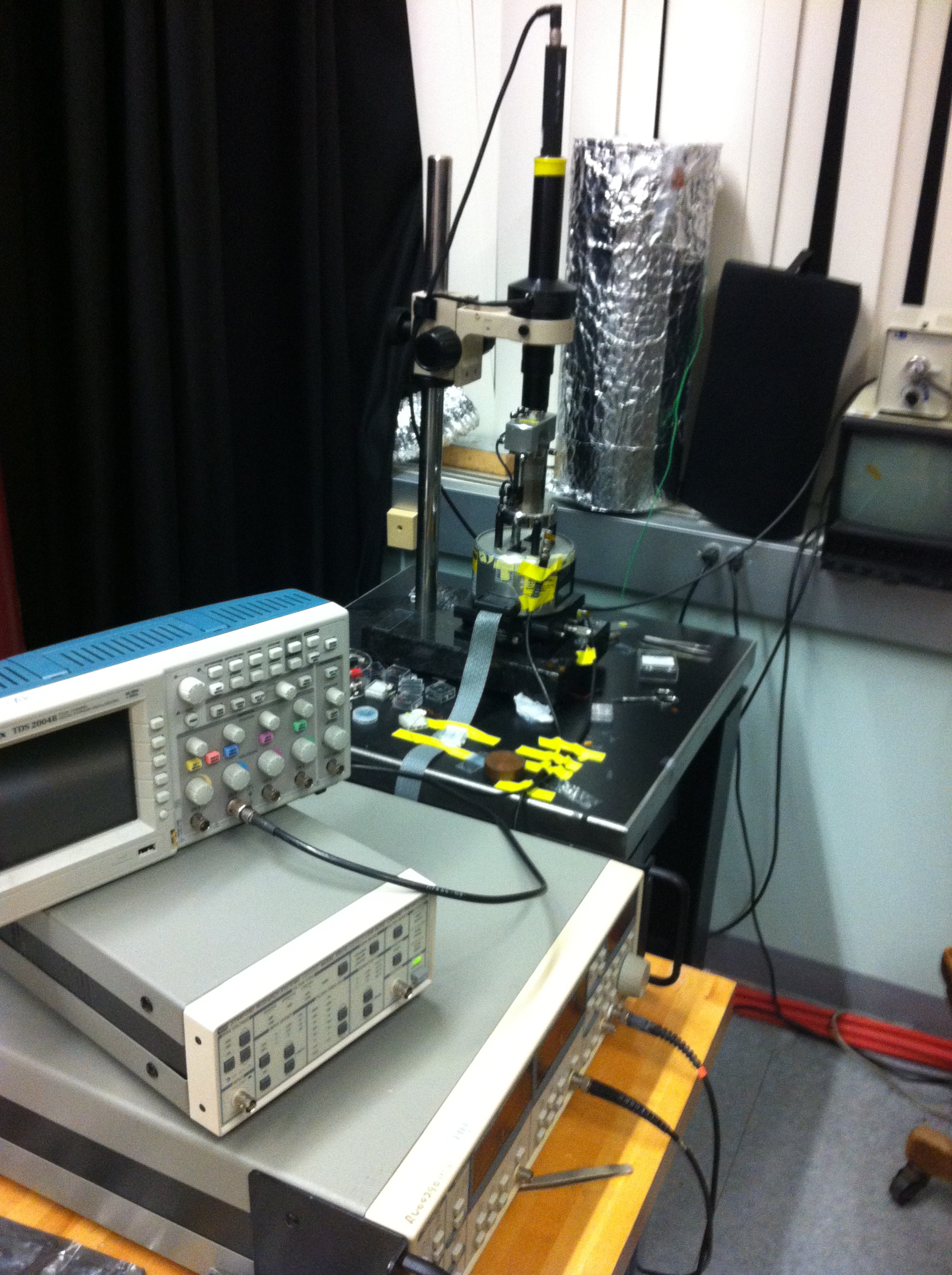

Scanning Tunneling Microscope

Low temperature STM provides spatial and energy resolution at the atomic scale reliably at a variable temperature down to 2K with a magnetic field up to 8T under ultra-high vacuum condition. The preparation chamber equipped with a sample heating stage and a sputter ion gun enables us to prepare an atomically clean surface. The system is also customized to adopt RHEED system and multiple thermal deposition sources for the future applications. |

|

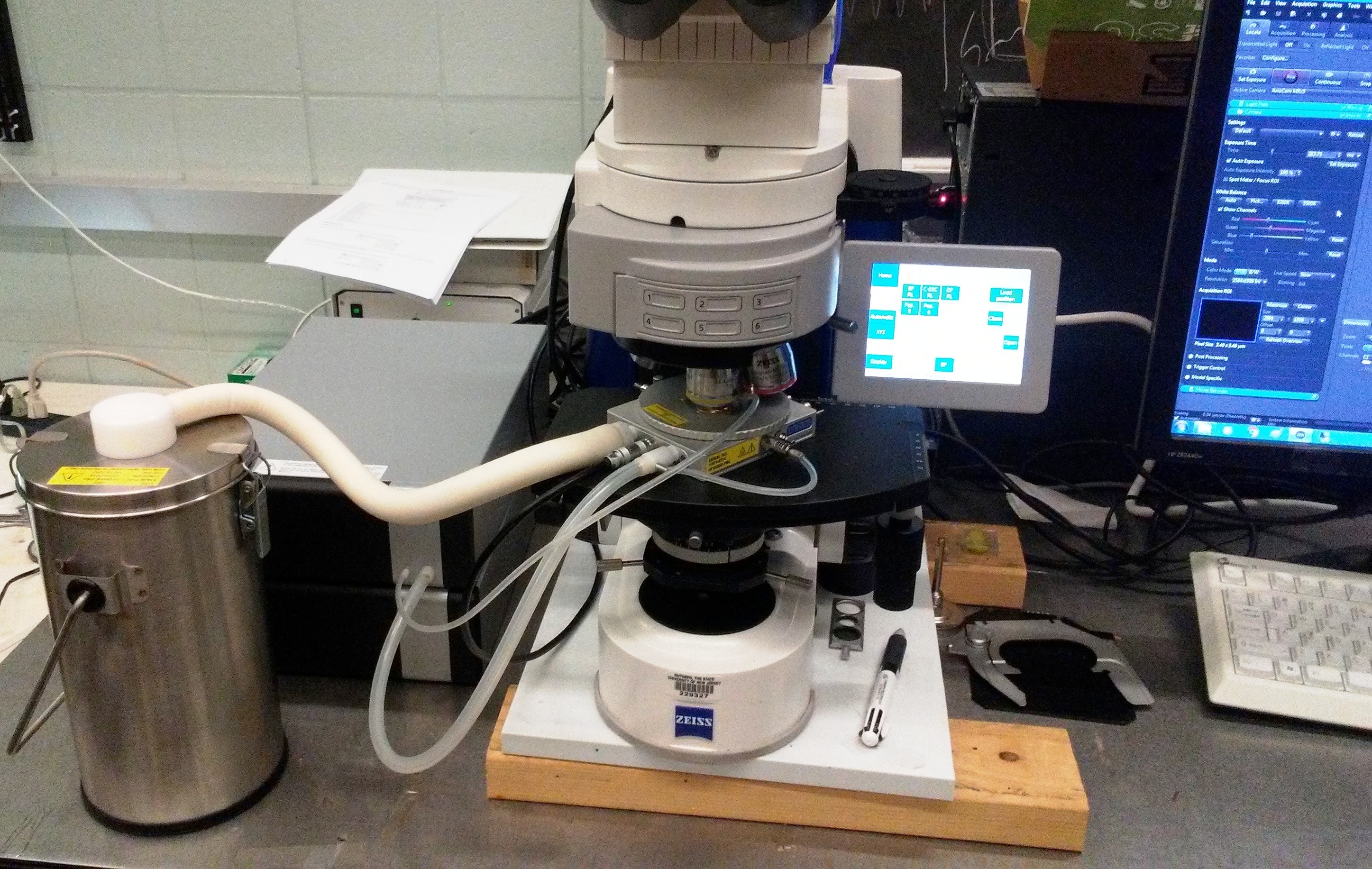

Temperature Controlled Microscope Stage

Linkam Temperature Controlled Microscope stage enables microscope imaging for samples in the temperature range -196° to 600°C, in both reflection and transimission mode. |

|

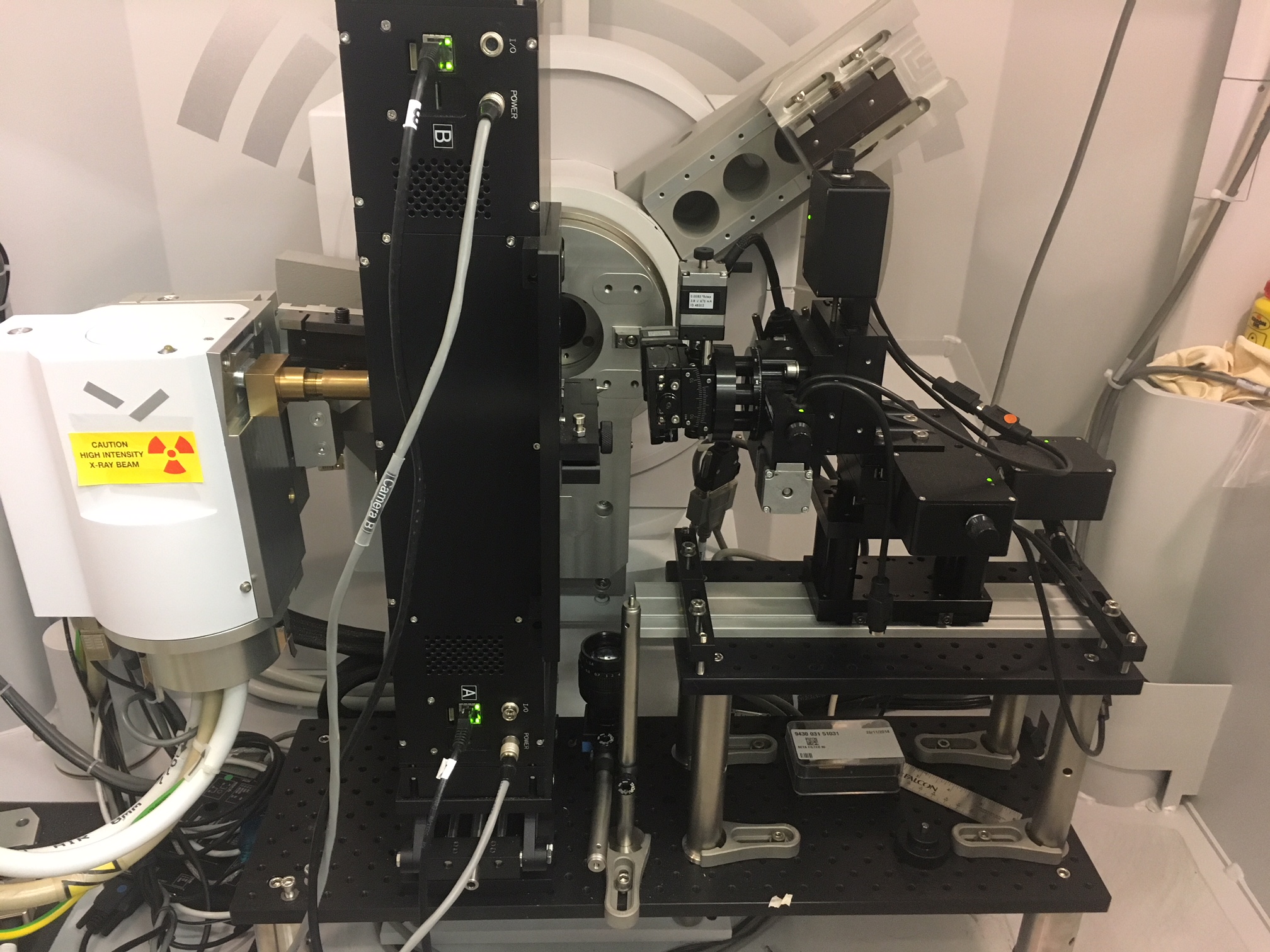

Photonic Science Laue camera

Photonic Science digital Laue X-ray camera upgrades the existing X-ray source of the X'pert3 diffractometer to allow crystal orientation with accuracy down to 0.5 degree, with a 6-axis motorized sample stage. |

|

Powder X-ray Diffractometer

Panalytical X'Pert3 Diffractometer features high resolution goniometer for powder x-ray diffraction and reflectivity for thin films, |

|

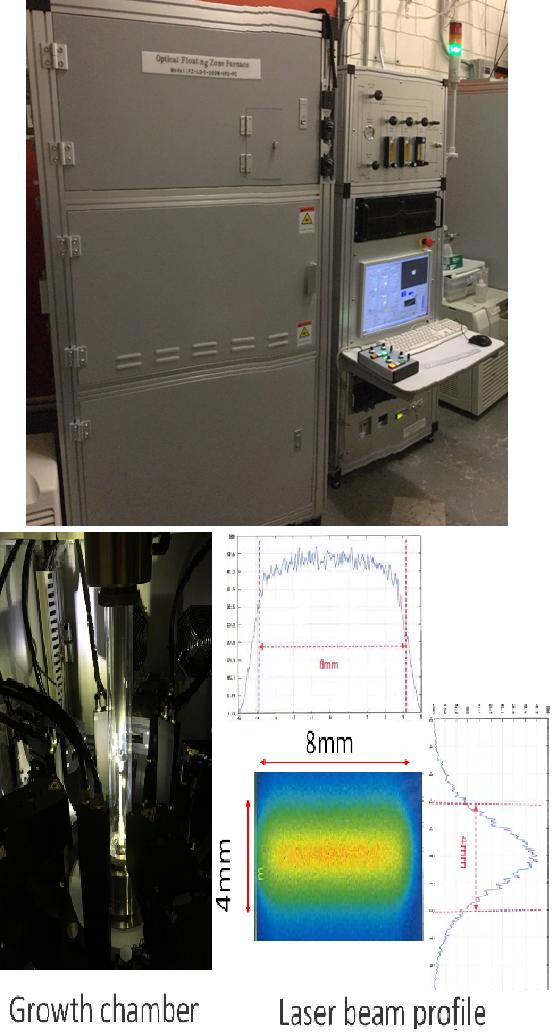

Laser Floating Zone Furnace

1000W Laser Floating Zone Furnace from Crystal Systems Inc. Highly focused molten zone enables stable single crystal growth of high melting, low viscous, volatile materials. |

|

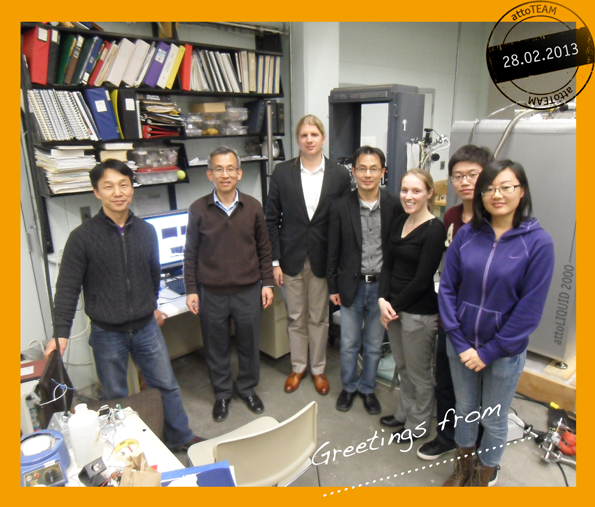

Low-Temperature Atomic Force Microscope

from Attocube (Feb, 2013 ) has been installed, capable of AFM, PFM, MFM, cAFM at low temperature and high-vaccum |

Quantum Design PPMS

a unique laboratory equipment which is optimized to perform a variety of automated measurements such as Heat capacity, Thermal conductivity, Magnetization, Dielectric constant and Resistivity. |

|

Quantum Design MPMS

used for performing the fundamental study of magnetism in research application of physics. MPMS sample magnetometers employ SQUID ( Superconducting QUantum Interference Device ) technology to achieve superior measurement sensitivity, dynamic range, and reproducibility |

|

|

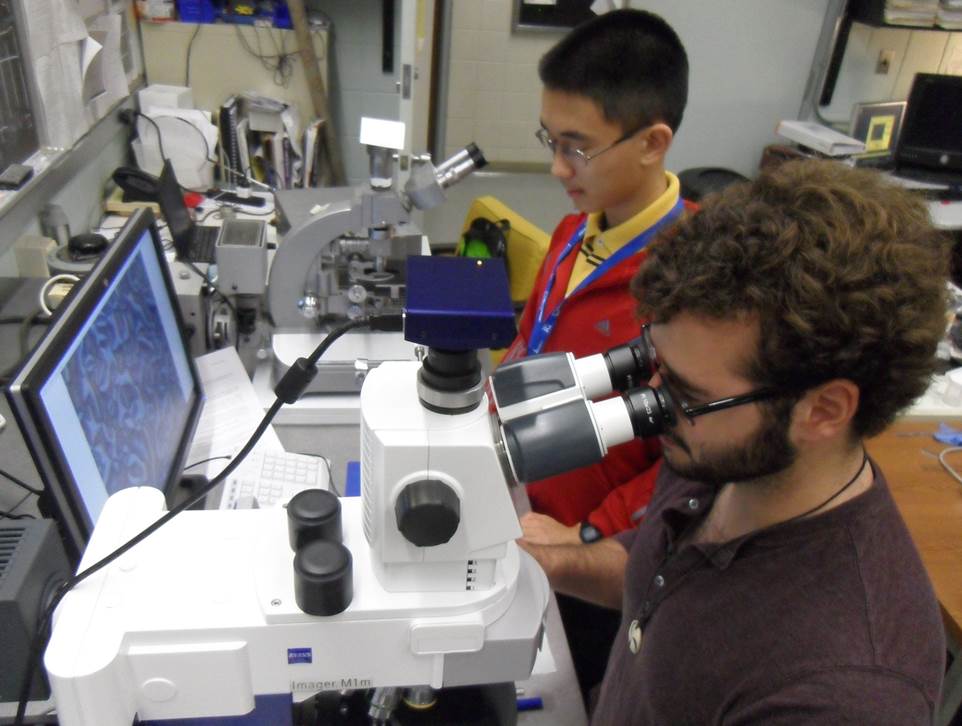

Carl Zeiss Axio ImagerFully motorized microscope with polarized light, sitting on a viberation isolation optical table, captures both reflection and transmission images of sample |

|

Transmission Electronic Microscopy (TEM)

widely used to characterize a lot of materials both from a morphological point of view and from the crystallographic but also for the elemental composition. Using TEM a large variety of materials as ceramics, minerals, metals, alloy, semiconductors, glass and polymers can be observed. |

|

Atomic Force Microscope (RT-AFM)

|

Glovebox

This glovebox workstation provides inert gas enviornment, less than 1ppm oxygen and moisture, for the preparation of air/moisture-sensitive samples. The purification system is fully automated and regenerable. |

|

|

Four-mirror Optical Floating Zone Furnace

Up to 120mm single crystal can be grown by this Four-mirror type floating zone furnace, which is made by Crystal Systems Inc. |

Pulsed Laser Deposition system (PLD)

The PLD method of thin film growth involves evaporation of a solid target in a High Vacuum chamber by means of short and high-energy laser pulses. In a typical PLD process, a researcher places a ceramic target in a vacuum chamber. A pulsed laser beam vaporizes the surface of the target, and the vapor condenses on a substrate. |

|

|

High-pressure Synthesis System (Big Blue)

Rockland piston-cylinder system with pressure up to 35Kbar is designed to synthesize high pressure phase of some material which can not be formed at normal atmosphere. |

High Pressure Oxygen FurnaceUpto 400 atomosphere at 1100C, it is an ideal furnace to use for annealing samples, preparing new materials under high pressure, and controlling oxygen stoichiometry. |

|

Lab Manual |